DELTA Supports Development of New Textile Reverse-Engineering Course

When you are hoping to discover how a system or object works, reverse-engineering is often the technique used to enhance understanding. After which, you can go forward to redesign and create similar products with added functionality. This can be a complex technique to understand — especially in an online format.

Professor Jesse Jur, Research Assistant Professor Amanda Mills and Ph.D. student Caitlin Knowles were awarded a DELTA Grant to create a new graduate-level online course focusing on the reverse engineering of textile products. The resulting TE 589: Design Analysis of Smart Textile Products course was created and offered by the Wilson College of Textiles to students during the spring 2022 semester.

The main learning objective of this course was to understand and apply reverse engineering principles to analyze and evaluate textile products. Then, to use the knowledge gained to redesign those products.

“Textile education is all about being hands-on! What we wanted to do in this program is make a virtual experience in textile education to be valued as much as a hands-on experience with the use of new technologies,” Jur explained.

The DELTA team working on this project was composed of Lead Instructional Designer Yan Shen, Instructional Media Producer Arthur Earnest, Lead Interaction Designer/Developer Ben Huckaby, Multimedia Development Team Lead David Tredwell and Assistant Director of Educational Media Donnie Wrights.

“The DELTA team is a dream to work with! They applied excellent project management skills to keep the progress on track. Moreover, they make your vision come true through the use of experts they have on staff who are focused on new distance education technologies,” said Jur.

Deliverables which were developed for this new course:

- Online Course Design and Development

- Virtual Models of Traditional and eTextile Products

- Videos of Designer Interviews

- Guided Reverse Engineering Projects

These deliverables did not focus on illustrating how to tear down the product. Instead, the focus was on understanding the design decisions used to create the product while observing the disassembly process — creating an environment for discovery.

A virtual garment product portal was created for each garment to allow students to explore the panels and components using a combined 2D/3D viewer. The students participated in reverse-engineering activities using the virtual product portal which purposefully guided them to inspect the product benchmarking analysis.

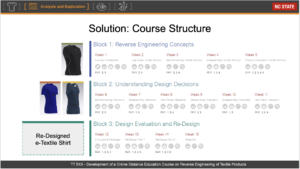

The resulting course was structured into three blocks with weekly cycles of conceptual learning. Students were assigned to watch video and complete readings followed by reverse-engineering activities which progressed from simple to complex. The last block requires students to critique the design of three garments and propose a redesign of the product.

Knowles, Mills, and Jur presented the work resulting from this grant at the American Society for Engineering Education Conference in June with writing support from their DELTA team.